Project

Mild Fractionation of Suspensions and Emulsions (modelling)

Introduction

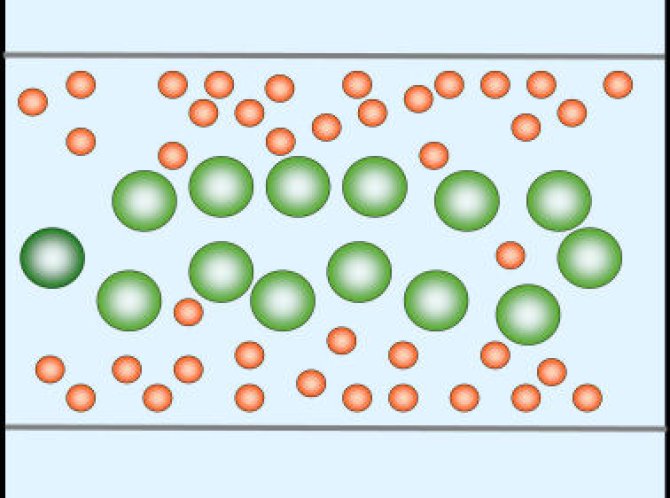

In the food industry, fractionation of components from foods with the aid of membranes is increasingly performed. A large disadvantage of fractionation with membranes is accumulation of components on or near the membrane, causing reduced flux. This cake layer formation is called fouling. The cake is not infinitely increasing in height, since there is also back-transport of particles from the cake towards the bulk. One of the back-transport mechanisms is shear-induced diffusion. This phenomenon occurs when particles are subjected to shear, which is created due to local differences in velocity. Particles diffuse to regions with low shear.

It was found that the shear-induced migration of the particles depends on the particle size. Larger particle migrate at a higher rate, with higher diffusion coefficient, compared to smaller particles. Therefore, shear-induced migration enables separation based on particle size. This makes it useful for fractionation of suspensions with variable particle sizes.

Shear-induced migration dominated flow over a membrane results in less large particles close to the membrane. Therefore, larger pores can be used to remove small particles while retaining larger ones.

Aim of the projectThe aim of the DSTI project is to obtain process conditions, system geometries and designs under which fractionation of particles, using shear-induced diffusion, is optimal.

Approach

The potential of shear-induced migration as basis for a less fouling-sensitive separation and fractionation process will be investigated by a mathematical model. The model will incorporate the most relevant physical processes.

As a start a continuum-based model for the flow and filtration of a monodisperse suspension will be used. The model will be extended to bidisperse systems. The bidispersity has several implications on the flow behaviour. These implications require development of new model components to capture the complex behaviour of polydisperse suspensions. The model will be validated with experiments.

The model can be used to study the effect of process designs. The gained insight should lead to increased fractionation efficiency and reduced fouling under mild processing conditions. This, in turn, reduces energy use and saves costs of separation in food industries, like dairy and beer.

This project is carried out within the framework of DSTI and is conducted in cooperation with Norit X-Flow, Friesland Campina and Royal Cosun.