News

Science: Closing the plastic cycle: bioplastic conversion into chemical building blocks

Due to a push towards the production of more nature-based materials, biobased plastics will slowly replace traditional oil-based plastics. But effective recycling, closing cycles, is crucial to make these new plastics sustainable. To be future proof, ETE scientists David Strik heads a project where he and his team are developing effective bioplastic recycling. ‘We have shown that microorganisms can effectively transform bioplastics into valuable chemical building blocks that can be reused.’

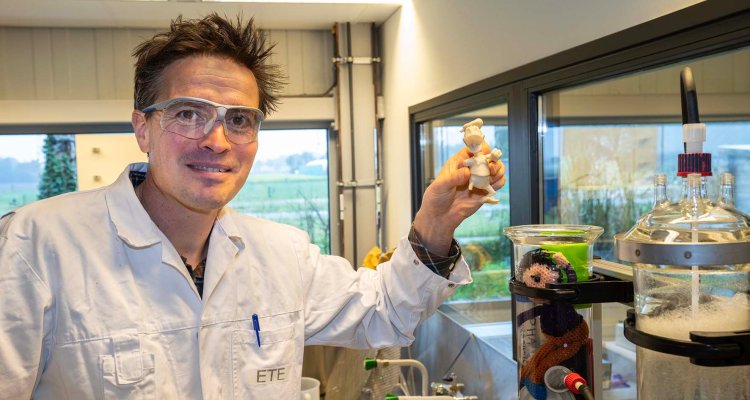

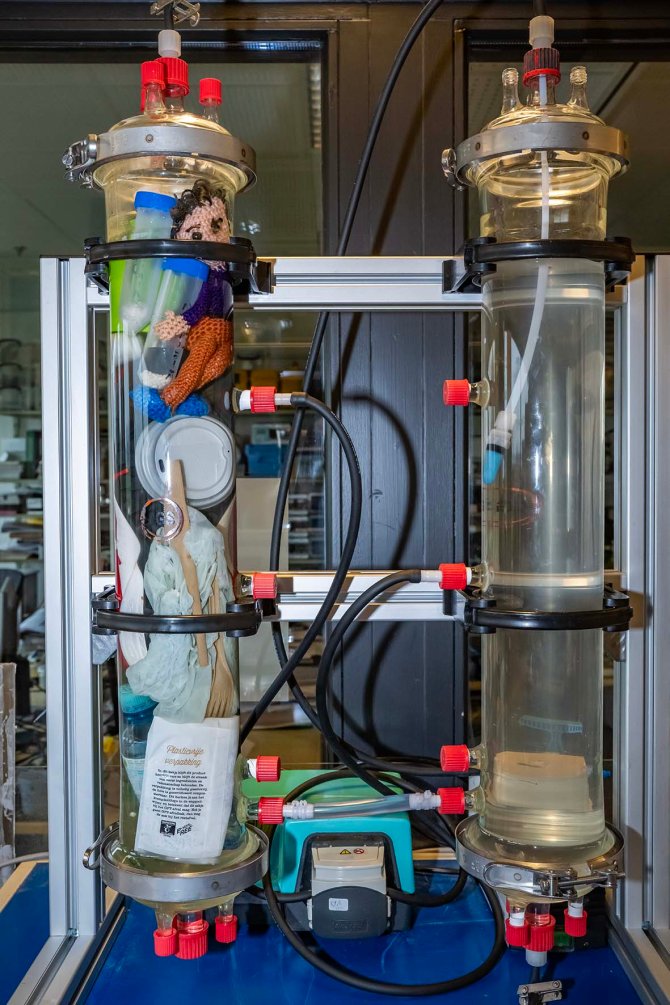

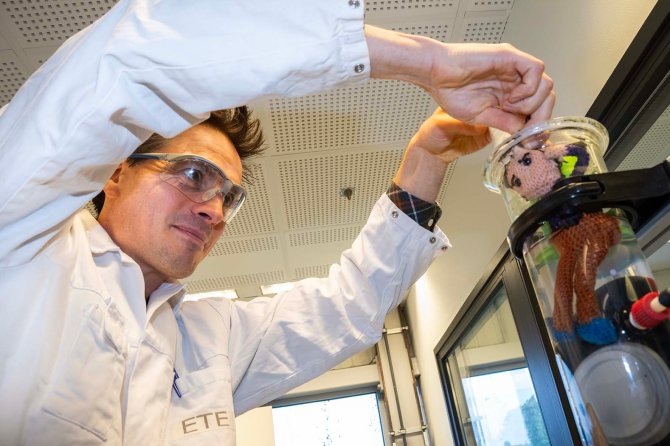

The lab at ETE sometimes holds some surprising features, but this is one of the most peculiar ever: a glass reactor column of about 50 centimeters high and 10 centimeters in diameter is stuffed with, what looks like, a pile of plastic waste: plastic toys, a spoon, a lid of a coffee cup and other undefined plastic garbage. A second column is filled with water, constantly aerated with stream of bubbles. Both columns are connected with plastic tubes, to allow a constant water exchange. ‘This is our demonstration reactor, where we illustrate our new project about plastic recycling’, ETE scientist David Strik says with a smile. He opens the reactor top and takes out a whitish plastic toy: ‘This is Donald Duck. He is made from bioplastic. During several weeks, microorganisms in the reactor will completely break him down. Over time, all these plastic items will be completely degraded.’ Although Donald’s future looks quite grim, he plays an important role in the experiments of Strik, that may change the world of plastic recycling.

Solve the plastic issue

Plastics are an indispensable part of our society with a huge variety of applications. However, if not managed properly, they are also a substantial source of pollution for the environment like soils, water systems, oceans, our food system and even our own body. The increasing use of single-use, disposable plastics accelerates this problem. Dealing with disposed plastics still is a problem. Plastics are partly mechanically downcycled, where it loses part of its original value, for example, by turning various types of plastic foils into plastic granulates that are used to make plastic buckets. In addition, significant amounts of remaining plastic waste materials are incinerated leading to pollution. Therefore, a transition towards biobased plastics, those made from biomass, could solve the plastic issue, especially if effective recycling technologies can be developed. ‘While plastics are very versatile and essential for society, the growing production of nature-based plastics with nature-based additives is eminent and needed’, Strik states. In his project he aims to develop technologies that will effectively reuse the future big volumes of biobased plastics, closing cycles and minimizing waste. And the first successful results are already published.

Versatile bioplastics

Strik’s project focuses on the most used biodegradable plastics. They all consist of polymers: long, chain-like molecules that consist of repeating, similar units, the so-called monomers. Polylactate (PLA)-based bioplastics are manufactured from lactic acid, originating from all kinds of plant-based streams, like sugars or other agri-food residues. The second type of biobased plastics are the poly-hydroxyl alkanoates (PHA), a very versatile family of bioplastics, made by microorganisms, that use it as energy storage. Finally, Strik is investigating, the so-called thermoplastic starch-based bioplastics, TPS used for bags or agricultural mulch films. Strik: ‘We are focusing our research on the efficient reuse and recycling of biodegradable biobased PLA, PHA and TPS mixtures.’

Closing the cycle

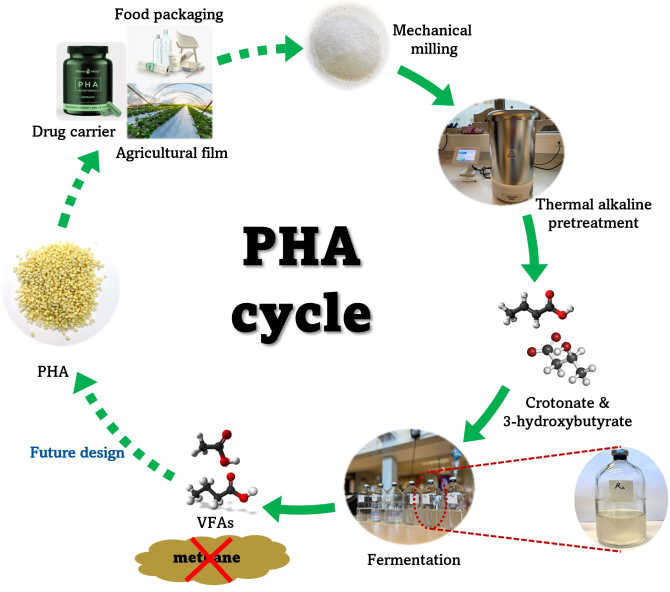

Strik’s aim is to develop a robust method to degrade the bioplastics into the so-called carboxylates. These chemicals are the building blocks of long-chained fatty acids, like caproate, acetate and butyrate. The industry can use these as raw materials to synthesize all kinds of chemicals, from lubricants, paints and also bioplastics, closing the cycle. The first step of Strik’s method is to breakdown the mechanically grinded bioplastics using hydrolysis, where the long, molecules are broken down into monomers, like crotonate and 3-hydroxy-butyrate (Fig. 1). ‘We aim to optimize reactor conditions, by tuning reactor temperature and pH for the best performance of a mixed microbial culture’, Strik explains. ‘This way we aim to achieve efficient chemical and biological hydrolysis of the microplastic mix.’ The scientists also want to find out which processes and conversions take place at different pH and temperatures. Strik: ‘This can be a real puzzle.’

Important building blocks

After hydrolysis, the second step involves anaerobic fermentation of the hydrolyzed bioplastic (Fig. 1). ‘In an open, mixed culture of microorganisms, obtained from a food waste fermentation process, the bioplastic monomers are fermented into a spectrum of carboxylates, important building blocks for many industrial products’, Strik explains. ‘One of the important conversions include the microbial transformation of lactate into acetate and propionate. These longer molecules also have more applications for the industry.’ Although the bioplastic waste streams are currently still too small to make large scale recycling a viable option, the first promising results from Strik’s research show the proof of principle. ‘We have convincingly shown that our methods works’, he says. ‘By using real bioplastic waste, consisting of a mixture of different bioplastics, we managed to eventually synthesize carboxylates by using hydrolysis combined with microbial fermentation.’

Bad news for plastic Donald Duck, whose fate looks grim, but he may be get a second life as another Disney figure or maybe a plastic spoon. And Donald’s rebirth is great news for bioplastic recycling and a more efficient use of precious commodities in our society.

Selected publications:

Microbial Recycling of Polylactic Acid Food Packaging Waste into Carboxylates via Hydrolysis and Mixed-Culture Fermentation. Strik, P.B.T.B. and Heusschen B. 2023. Microorganisms11(8), 2103. https://www.mdpi.com/2076-2607/11/8/2103