Why are there so few alternatives to harmful PFAS?

PFAS (per- and polyfluoroalkyl substances) are notorious chemicals that may soon be banned. A number of countries including the Netherlands have submitted a proposal for such a ban, and this is due to be considered by the European Commission in 2025. This means that we urgently need substitutes for PFAS – so why don’t we have them yet?

On any given morning you’re likely to be exposed to PFAS multiple times, sometimes without even realising it. PFAS are all around us: from the pan you use to fry an egg, to the raincoat that protects you from a sudden downpour, the moisturiser you rub onto your face and the mascara on your lashes. These substances are derived from fluorine and are known for their ability to repel oil, dirt and water. That’s useful for non-stick coatings and textiles, but PFAS also pose a hazard to human health and to the environment. Why haven’t scientists come up with a safe alternative?

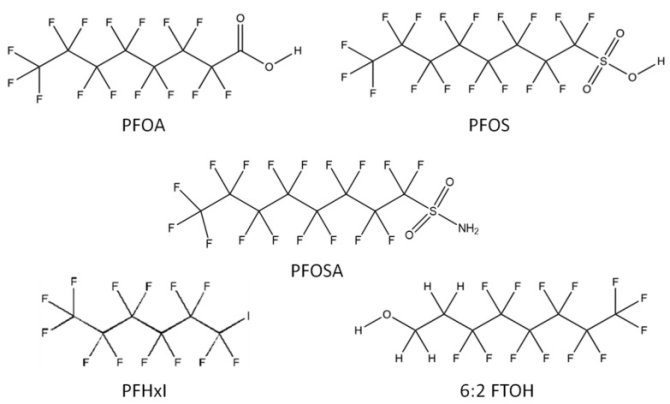

Strong fluorine bonds

PFAS are chemically unique. Almost all molecules are attracted to either water or fat. PFAS sit somewhere in between. This is due to the amount of fluorine in PFAS, which makes them completely resistant to water, grease and dirt. These fluorine bonds are what make PFAS so useful, but the bonds are also particularly difficult to break down. The breakdown process is slow, and toxic degradation products accumulate and cause harm to the environment, humans and animals. Because the components that make PFAS useful are also those that cause problems, it’s not easy to replace them with a safe alternative.

However, it’s already possible to buy pans that don’t have a PFAS non-stick coating. Manufacturers have achieved this by applying a ceramic layer.“But that’s a hard material and you can’t use something like that for waterproof clothing or cosmetics, for example,” says Jacco van Haveren, programme manager for Safe and Circular Biobased Products at Wageningen University & Research (WUR). And that’s precisely one of the key problems: there are more than 12,000 different PFAS molecules.

One type may be great for flexible materials such as textiles, while another will be useful for fire-retardant foam and yet another produces high-quality cleaning products. “We’ll never be able to replace all of those PFAS molecules on a like-for-like basis,” explains Van Haveren. “So we have to focus on the ways they’re used.” A water-repellent additive for rain gear can also serve as a coating for pizza boxes, for example. But it’s still a lot of work. You might think it’s a matter of all hands on deck, but the reality is that it’s easier said than done.

Emphasis on monitoring

While the harmful effects of PFAS are becoming increasingly clear, and the urgency of alternatives is growing, very little research is being done to develop alternatives to PFAS. “Instead, the focus is still on monitoring the substances,” says Van Haveren. At Wageningen, too, scientists are mainly involved in observing PFAS. That’s why Van Haveren is calling for large-scale research into alternatives. “So far, scientists haven’t dared to tackle this problem properly, simply because it’s really very difficult,” he says. This year, Van Haveren co-launched a study into alternatives to PFAS. “Right now, we’re focusing on the group of essential PFAS. From my point of view, that includes packaging and coatings.” He also hopes to find an alternative to PFAS for the special membranes used to produce hydrogen gas from water for use as fuel.

Raw materials

PFAS alternatives have to come from somewhere. In other words, you need raw materials. “If we don’t want PFAS and we want to replace them with something better, we probably shouldn’t resort to petrochemical components,” says Daan van Es, research associate in Sustainable Circular Chemistry. Instead, he says, science should look for components found in nature. The advantage of such components is that they’re biodegradable and therefore do not accumulate the way that PFAS do. There’s actually an abundance of potential natural substances. Beeswax is a great example, with its water-repellent characteristics. It’s a safe, functional product, and it’s biodegradable. “But if we have to replace 20,000 tonnes of PFAS with beeswax, we’ll have a problem,” says Van Es. “We don't have enough bees for that, and we shouldn't be aiming for that.” Scale is therefore another problem.

Even if scientists were to produce the substances industrially, scale would remain a challenge. “We might need a few hundred or a few thousand tonnes of some substitutes every year. No one is going to open a factory to produce on that kind of scale,” says Van Es. Especially given that the industrial sector generally tries to avoid having to make modifications. “Modifications represent additional costs,” Van Haveren explains. “That’s why the first approach taken by companies is to demonstrate that potentially harmful substances are not in fact harmful after all, which is also what happened with PFAS.” Those studies sometimes take decades, and it’s only when the research unequivocally shows that substances are unhealthy that the search for substitutes begins. “We saw the same thing with heavy metals in plastics and in paints,” says Van Haveren.

The future of PFAS-free products

At first it was a lack of clarity about the adverse effects, but now it’s mainly the chemical complexity and huge variety of PFAS that make it really difficult for researchers to come up with new solutions that match the water, oil and dirt repellent qualities of PFAS. Initial studies into non-PFAS solutions are now underway, but Van Haveren doesn’t expect them to be on the market within the next couple of years. “The easy stuff has been done, and now we have to immerse ourselves in the complex chemistry,” he says.

So, there’s no quick fix on the horizon, but if Europe does indeed implement the ban on PFAS by 2025, time is running out. Research institutes and industrial players need to shift their focus from monitoring to the development of PFAS alternatives. With additional government funding and smart policy measures, scientists could crack that complex chemistry and make progress on expanding the range of PFAS substitutes.